This blog post is an excerpt from Authority Magazine's series "The Future of Robotics Over The Next Few Years" . View the original article here.

What can we expect to see in the robotics industry over the next few years? How will robots be used? What kinds of robots are being produced?

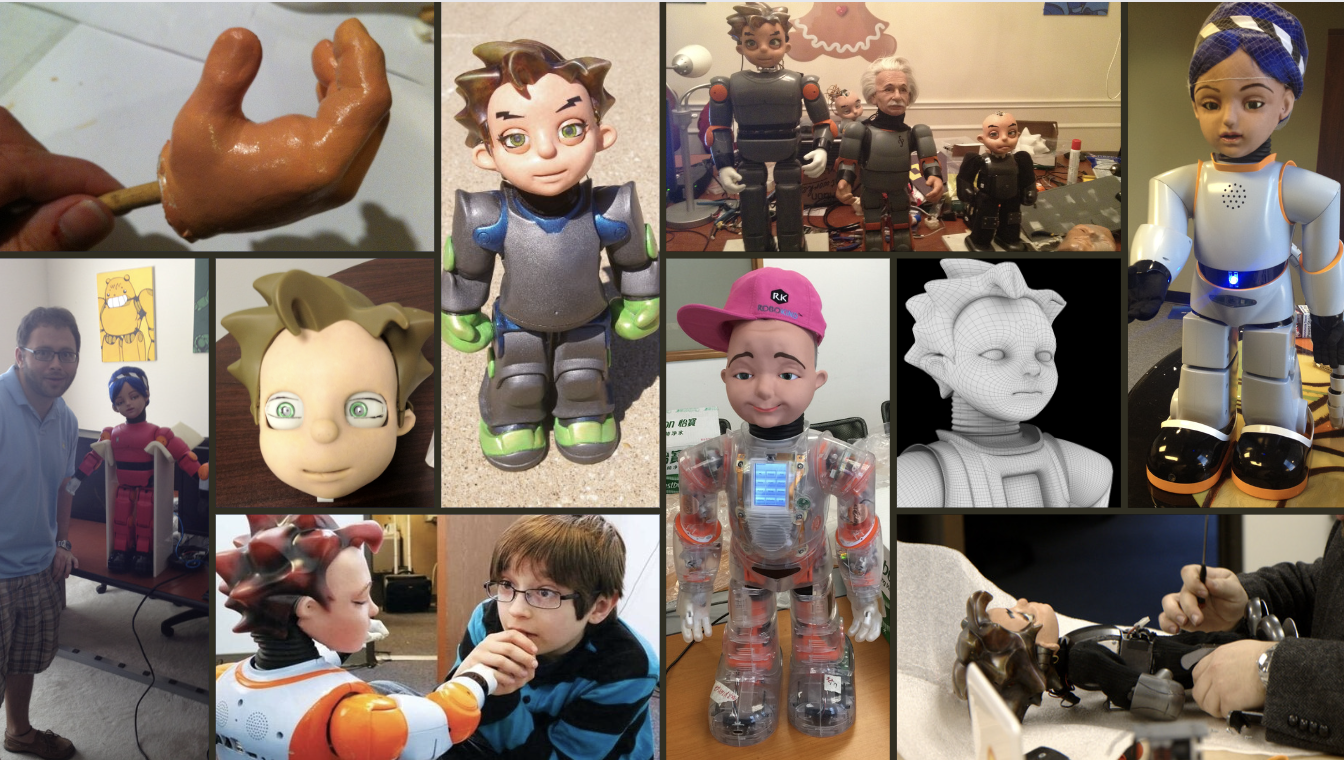

In Authority Magazine's series called “The Future Of Robotics Over The Next Few Years”, David Leichner interviewed leaders of Robotics companies, AI companies, and Hi-Tech Manufacturing companies who shared insights from their experiences. I was happy to be one of the roboticists featured in this series.

Here are my 5 tips for creating a successful future in robotics.

1. Be good at solving problems, and okay with failing.

Every project has its bugs. You need the drive to find the root of the issue and try new ideas. Make rapid prototypes until you form your own solutions.

During RoboKind’s early years, we needed a system for animating the robots. We built a new application from scratch since our robot technology was also new. We had the idea to use existing 3D animation software to drive the robots, something no other robotics company was doing at the time.

As a team, we shared our respective specialties as animators and software engineers to creatively solve problems together. It is oddly humbling to not Google the answers to our questions. We realized, we are creating something completely new every day.

2. Understand all types of engineering.

Robotics is not one area of study. It combines many types of engineering (and art). If you are interested in robotics, start by understanding engineering in the following areas:

- software

- electronics

- mechanical

- manufacturing

It seems like a lot, but understanding how these different fields of study interact is crucial for communicating between development and manufacturing teams.

I like to relate the different engineering fields to that of the human body. Software engineering is the brain. Electronics are the nervous system, as it provides the inputs and outputs for the brain. Mechanical engineering is the bones and structure. They have to all work together to create our bodies and help them properly function.

3. Design with manufacturing in mind.

As an engineer, everything you design will then be manufactured, assembled, and used in the real world, not in a lab. I believe in fast prototyping to prove ideas around mechanics and electronics.

In college, I was working with a group to create a sock puppet robot to tell stories for a children’s event. The first design contained complex linkages, four bar mechanisms, and was made from material the servos couldn’t handle. It included 40 custom parts needing to be printed, machined, and welded to create the robot. It was complex. More complex than it needed to be.

We simplified the design to six bent sheet metal pieces. The robot was literally going to be covered by the sock puppet. No one would ever see the inside of the robot. All we needed was a few servos stacked to make a snake-like movement and something to drive the mouth on the end.

When you understand how your design will be made and used, it changes your approach to design and testing.

4. Be Minimalistic and Cost Effective.

In the previous story about the snake robot, I mention I ended up using simple springs and scrap metal we had lying around to complete the robot snake project. The cost to produce custom parts for any design comes with a price tag. I don’t recall the manufacturing cost of the snake robot, but scrap is cheap and sometimes free.

When I got my first job designing and building robots, I took the time to learn about materials, manufacturing processes, and how to prototype with limited time and resources. These skills have helped build my robotics career.

5. Find your specialty.

Not all robots are created equally. In my case, I’ve been lucky enough to work in the realm of humanoid robots to help individuals on the autism spectrum. There are endless sub-fields and specializations one could make a career out of in the robotics industry. You could develop semiconductors, design new forms of actuation, the list goes on — and the possibilities are infinite.

My best advice is to do what you're passionate about and use your skills to help others. Trust me, it's rewarding.

Follow me on Twitter or connect with me on LinkedIn to keep this convo going.